Simple and Actionable In-Situ AM Inspection from your Layer Camera Data

Use Your Existing In-Situ Layer Camera

No hardware to purchase or install

Notify Operators of Live Build Issues

Live alerts if customized anomaly limits are violated

Automatic Build Reports for SDRs

Build Reports contain the information needed to disposition Supplier Deviation Requests (SDRs)

Solid Models of Build Anomalies

Automatically generate solid models of build anomalies.

“LAMQC tells us if the build is acceptable and documents the quality of every build.”

“If the build is questionable, LAMQC provides the information required to disposition the Supplier Deviation Request (SDR).”

Possible In-situ Monitoring Outcomes

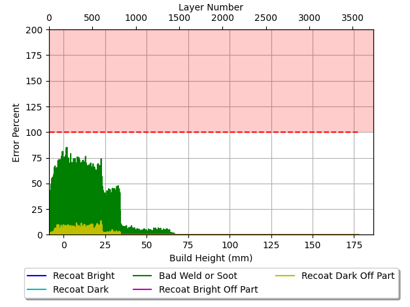

Acceptable Anomalies

Builds that meet ALL requirements should be accepted and continue the manufacturing router.

No anomalies exceed limits into red-zone.

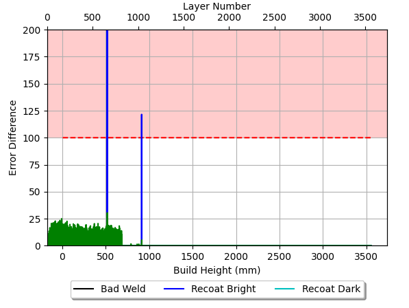

Minor Anomalies

Builds with minor, local anomalies that violate requirements for build size, type and location should be sent to the AM purchaser for acceptance as an Supplier Deviation Request (SDR).

Minor anomalies exceed limits into red-zone.

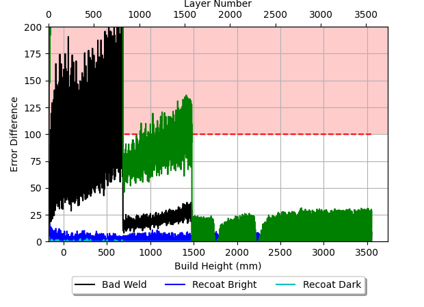

Major Anomalies

Builds with major anomalies that violate requirements for build size, type and location should be terminated as soon as operators are notified.

Major Anomalies exceed limits into red-zone.