1. General Information

Unique report identifier, material, and build name

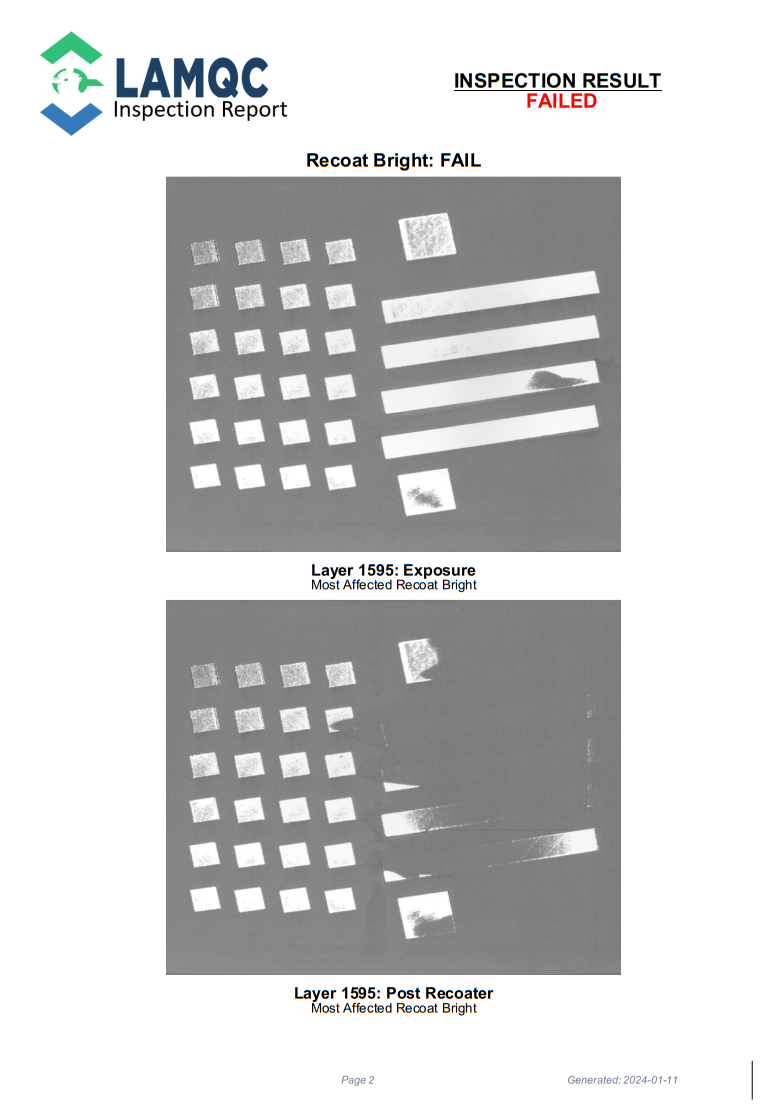

2. Inspection Summary

Tabular anomaly sizes with respect to build limits

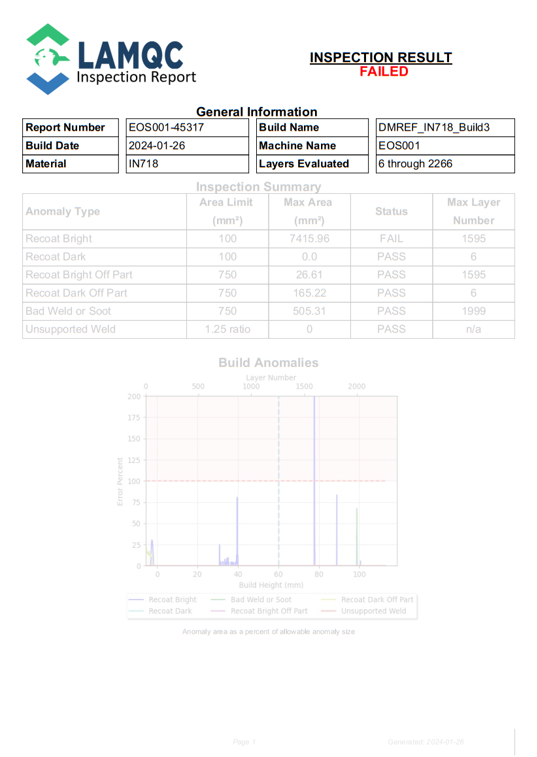

3. Build Anomaly Graph

Graphical anomaly sizes with respect to build limits

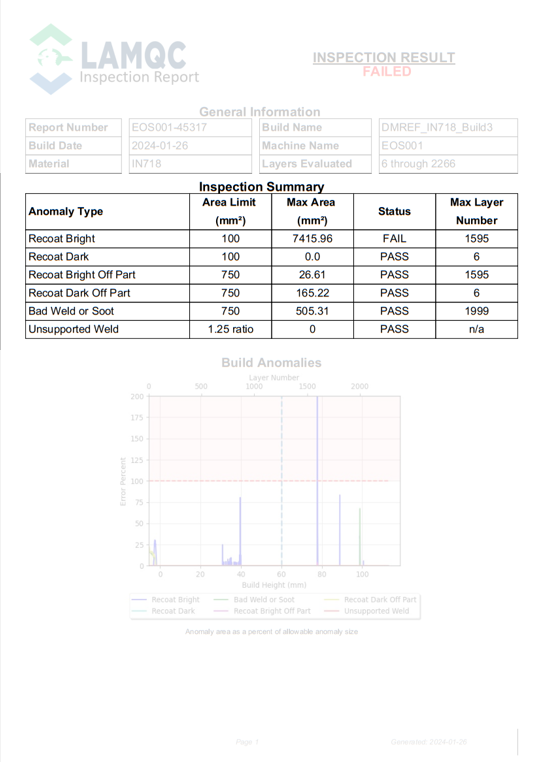

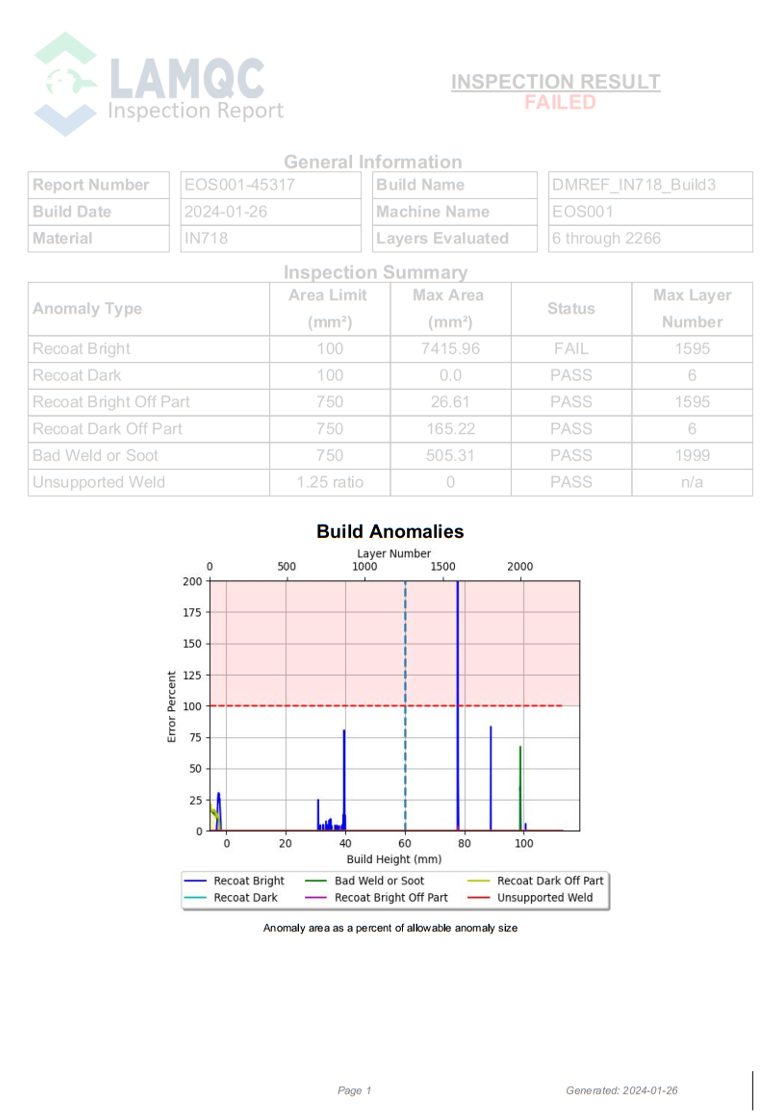

4. Layer Camera Images

Limited, relevant layer camera images.

General Information

The first section of the LAMQC inspection report is General Information. This section contains build identification details such as:

- Report Number: Auto-generated unique Inspection Report identifier

- Build Date: Date of AM build (when used Live)

- Material: AM powder

- Build Name: User generated build name

- Machine Name: Company specific AM machine name or number

- Layers Evaluated: The evaluated layers included in the inspection report.

Inspection Summary

The Inspection Summary presents build quality information for each anomaly type in a table, including:

- Area Limit: The maximum allowable anomaly area

- Max Area: The maximum recorded build anomaly area

- Status: PASS / FAIL. If Max Area exceeds Area Limit status is FAIL

- Max Layer Number: The layer number of the maximum anomaly area

In this build, only Bright Recoat has failed inspection requirements.

The anomaly limit is 100 mm2 and LAMQC found a Bright Recoat anomaly with an area of 7,415 mm2 at layer 1595, resulting in a “FAILED” build.

Build Anomalies Graph

The Build Anomalies Graph section of the Inspection Report illustrates how the size of each anomaly progresses over the build.

While this build failed to meet Bright Recoat requirements, the graph shows that the build quickly recovered from each anomaly.

If the parts in this build will not be used in a critical application, the build may be acceptable. This inspection report and the solid models should be provided to the AM Purchasers to disposition this build.

However, if the parts in this build will be used in a critical application with well defined acceptability limits, it should be scrapped and not be allowed progress down the manufacturing router.

Its important to note that the Build Anomalies Graph presents anomaly size at a give build layer, but does not present the location of the anomaly relative the AM part(s). Understanding the location of the anomaly with respect to the AM part(s) requires the use of LAMQC anomaly solid models.

Layer Camera Images

LAMQC understands that reviewing 200 images per build is just as impractical as reviewing 2000.

Therefore LAMQC Inspection Reports only contain layer camera images of anomalies that most significantly exceed build limits.

In other words, a LAMQC Inspection Report will include no more than 12 images, comprised of an exposure and recoater image for each of the six anomaly types.

In this example, only Bright Recoat anomalies exceeds limits. Consequently, the LAMQC Inspection Report includes only Bright Recoat layer camera images of layer 1595, the layer with the largest Recoat Bright anomaly.

If the AM Purchaser considers this anomaly acceptable, we recommend that the AM Purchaser investigates increasing Recoat Bright anomaly limits.