Our second published case study illustrates LAMQC’s ability to find a hidden build failure and unsupported weld with in-situ inspection.

As before, the goal of the case study is to show:

- What an operator would have known.

- When they would have known it.

- What they could have done about it.

In particular, this case study will show the use of LAMQC solid models to inspect the quality of individual parts from layer camera data.

In this build, only 130 layers of the 800 layer build contain anomalies that a trained operator would have noticed. It is likely that these build anomalies would not have been caught in many AM facilities.

This 800 layer build started properly and ended properly. Significant build anomalies occurred on only 130 layers in the middle of the build.

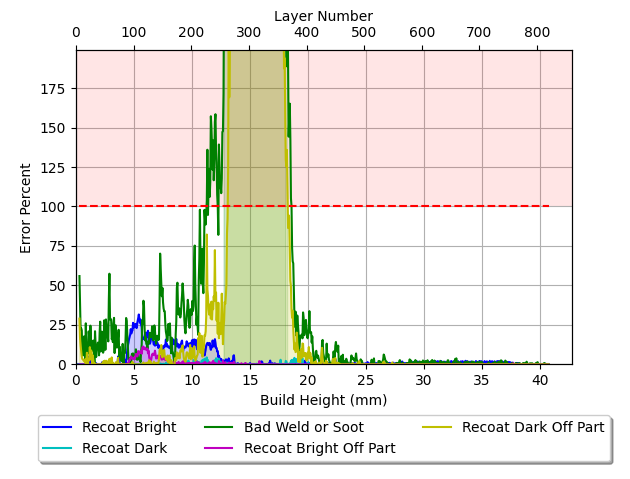

Build Anomalies Excluding Unsupported Weld

The Build Anomalies Graph illustrates significant Bad Weld or Soot anomalies from layers 220 to 350.

The Bad Weld or Soot event is transient and, from this graph, it appears that the build has recovered.

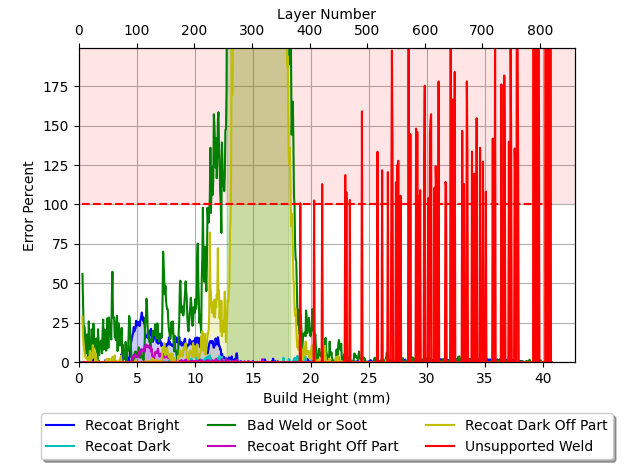

Build Anomalies Including Unsupported Weld

The addition of Unsupported Weld anomalies to the Build Anomaly graph illustrates that the second half of the build did not behave as expected and instead produced unacceptably large Unsupported Weld anomalies.

Unsupported Weld anomalies are weld that starts in the middle of the build without weld in the prior layer. Unsupported Weld is the single most serious build anomaly as layer adhesion, surface roughness, LCF and tensile results are often negatively impacted in these regions.

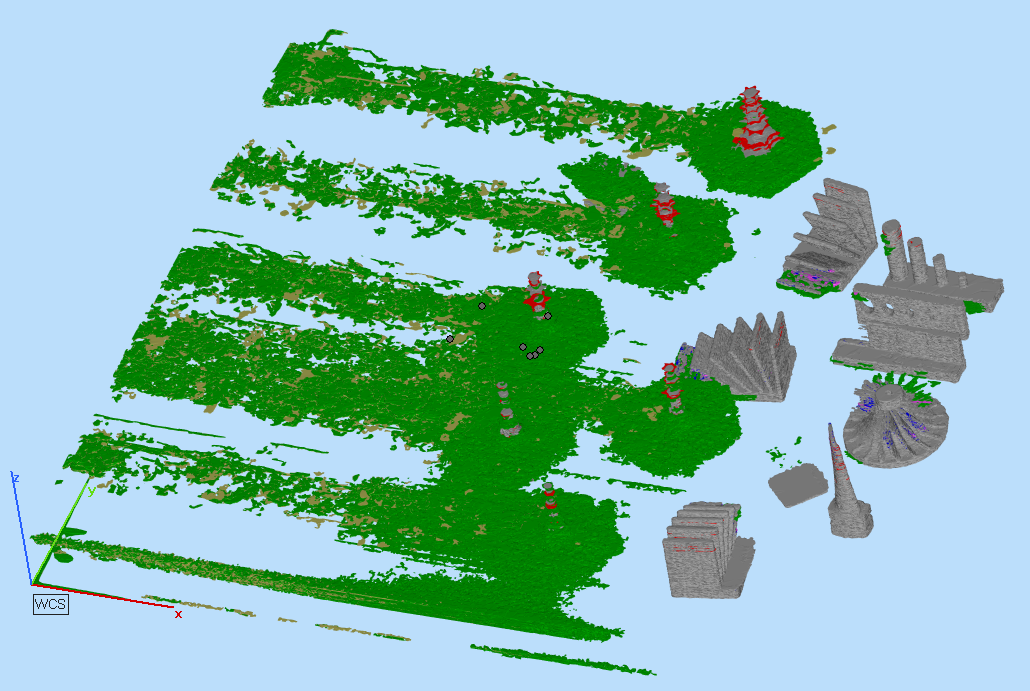

Build Anomalies – Solid Model

The anomaly solid models for this build indicate significant build issues on the left half of the build including Unsupported Weld (red), but less on the right side of the build. An AM operator would be reasonably tempted to assume the parts on the right side of the build plate are acceptable.

In the next section we will use LAMQC solid models to illustrate why that would have been a costly mistake.

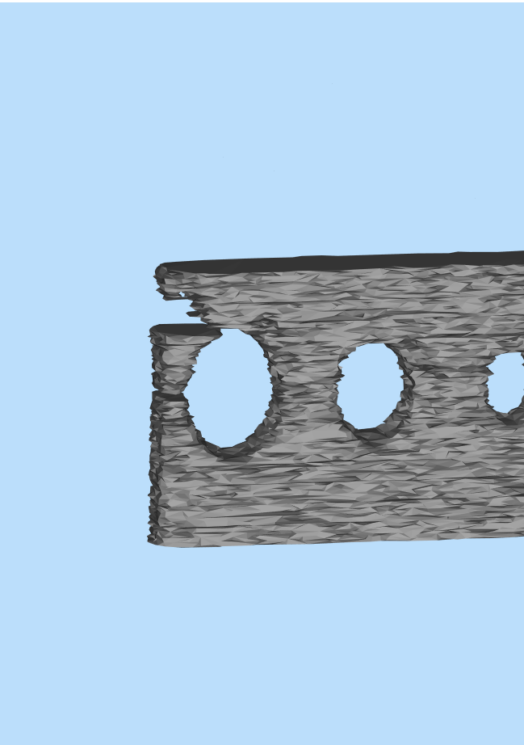

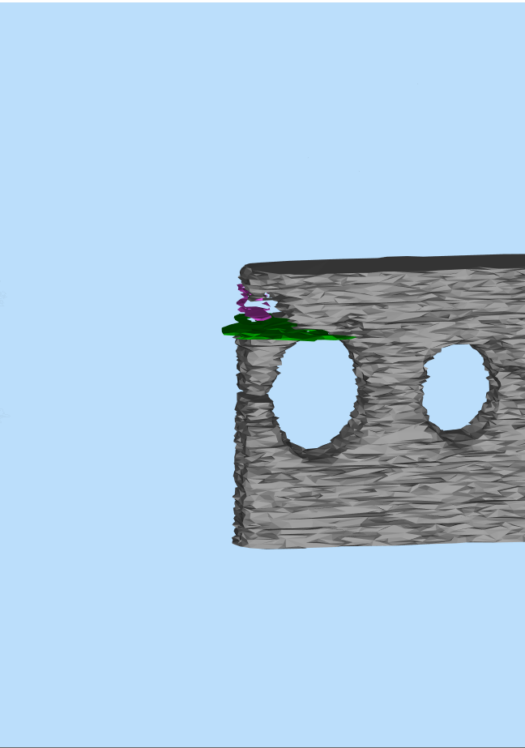

Note that the solid models appear “rough” due to the low (700×700) resolution images. Higher resolution images improve solid model fidelity.

Part Details: Unknown

This part is one of the 6 parts on the left of the build plate. The parts have failed so completely that the part geometry is unrecognizable. It is likely that these 6 parts would have been immediately scrapped after the build.

The solid models show that there is a large region of Bad Weld or Soot (green) in the center of the part (left image).

Additionally, LAMQC shows that there are significant gaps in the weld (grey), accompanied by Unsupported Weld anomalies in red.

Unknown Part: All Anomalies

Non-continuous weld visible.

Bad Weld or Soot (green) removed.

Non-continuous weld visible.

Part Details: Overhang Block

This overhang calibration block illustrates the ability of LAMQC to detect anomalies on low angle overhangs that present problems on many LPBF AM machines.

The left image shows the weld (grey), along with the build anomalies, Bad Weld or Soot (green), Bright Recoat (blue) and Bright Recoat Off-Part (purple).

As expected, the lowest angle overhang contains the most anomalies, followed by the second-lowest angle overhang.

Overhang Block: All Anomalies

Significant anomalies at lowest angle.

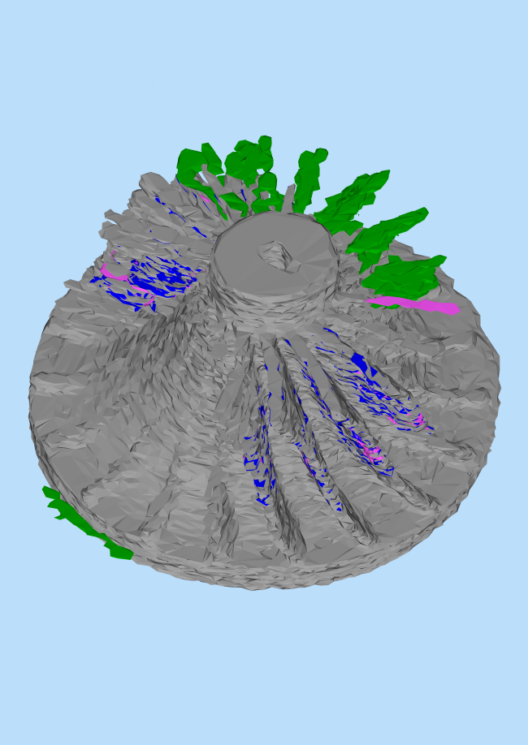

Part Details: Impeller

The LAMQC solid models clearly show that the top impeller vanes experienced significant Bad Weld or Soot and many of the vanes experienced Bright Recoat anomalies.

A close inspection of the weld region (grey) on the left image shows that the vanes on the left side of the impeller failed to print properly. LAMQC does not consider these vanes to have printed with “weld”, resulting in the vanes failure to appear as “weld” in the solid models.

Impellers operate at a high rotational speed and high stress. Any build anomalies or lack of weld should result in a scrapped part.

Scrapping the part during AM by stopping the build saves AM costs associated with powder and machine time as well as post-AM manufacturing and inspection costs.

Scrapping the part after AM savings time and costs associated with post-AM manufacturing operations and inspection.

Impeller: All Anomalies

Weld: Grey

Bright Recoat: Blue

Bad Weld or Soot: Green

Part Details: Turbine Blade

This turbine blade has both Bright Recoat (blue) and Unsupported Weld (red) build anomalies.

Unsupported Weld is present in the turbine blade at the perimeter of the blade. The weld cross-sectional area in the layer camera images grows and shrinks over the build height, not the design intent of a constant taper. Significant Unsupported Weld negatively impacts surface roughness, tensile properties and LCF life.

Turbine blades operate at a high rotational speed and high stress. Any build anomalies should result in a scrapped part when they become apparent.

Scrapping the part during AM by stopping the build saves AM costs associated with powder and machine time as well as post-AM manufacturing and inspection costs.

Scrapping the part after AM savings time and costs associated with post-AM manufacturing operations and inspection.

Turbine Blade: All Anomalies

Welded Region: Grey

Bright Recoat: Blue

Unsupported Weld: Red

Part Details: Calibration Block

This calibration block has both Bad Weld or Soot (green) build anomalies as well was Bright Recoat of Part (purple) but the most striking part of this calibration block is a section of missing weld.

Running this build in LAMQC Frozen Process would have highlighted the missing weld as a separate anomaly, allowing easier detection.

Look for this calibration block example in the near future as part of the LAMQC Frozen Process demonstrations.

Calibration Block: All Anomalies

Welded Region: Grey

Bright Recoat Off Part: Purple

Bad Weld or Soot: Green

Unsupported Weld: Case Study Summary

1

What an Operator would have known.

The operator would been made aware of the large Bad Weld or Soot anomaly on layer 220 as well as the Unsupported Weld anomalies. The operator can then review relevant layer camera images, the anomaly graph and solid models of the build anomalies.

2

When they would have known it.

The operator would have been notified of the Bad Weld or Soot anomaly immediately with an email alert, and if the build continued, additional alerts regarding Unsupported Weld. The other anomalies would have been visible in the LAMQC graph and solid models.

3

What they could have done about it.

Shut down build. This build has significant and persistent build anomalies. It should be shut down for all AM part use-cases, even for prototype parts.