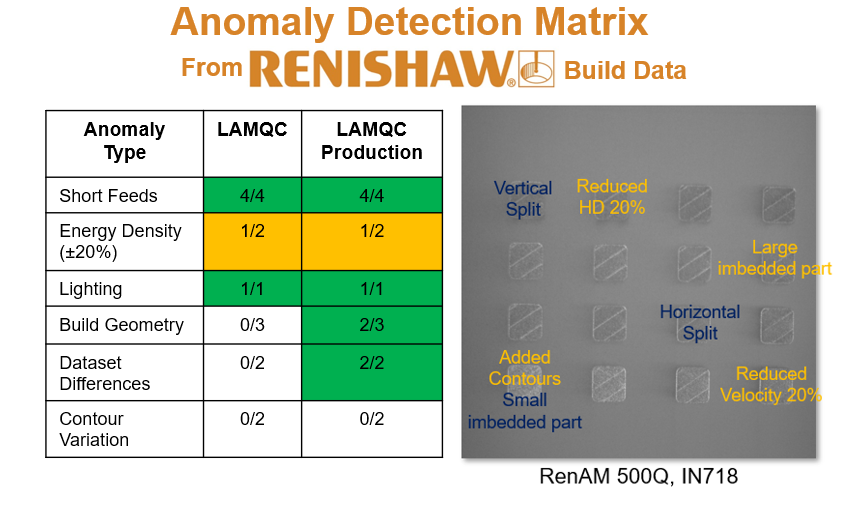

If you can see it on layer camera images, we can see it in LAMQC.

LAMQC uses your existing in-situ layer camera data to highlight build anomalies for AM production and prototyping applications.

Anomalies visible on in-situ layer camera images often negatively impact mechanical properties and build repeatability.

Using existing layer camera images limits LAMQC’s ability to directly detect anomalies that are not visible in layer camera images.

Detectable Build Anomalies

Unsupported weld, soot, defective weld, short-feeds, coater tears, peel-ups, super-elevation.

Each of these anomalies are visible in layer camera images and are visible in LAMQC.

Non-Detectable Build Anomalies:

Energy density variations less than ~20% (material and parameter dependent), spatter particle tracking, individual pockets of porosity or key-holes, 1 vs 2 contours.

These anomalies are not visible in layer camera images and not visible in LAMQC. Minor laser power variations are visible with optical tomography (OT) data.

LAMQC detects anomalies that appear in layer camera images